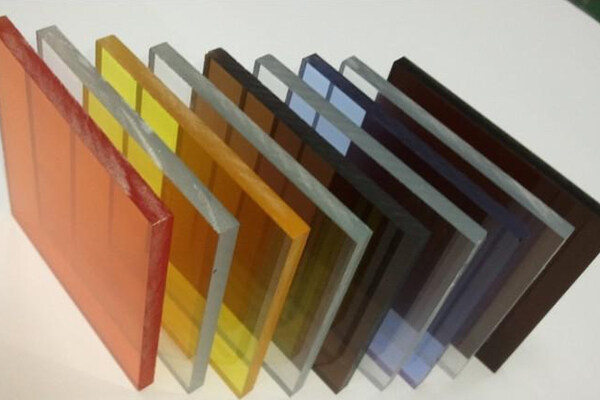

Acrylic board is widely used in life, ranging from stationery accessories to mechanical equipment. So how did acrylic try to cut it? Xiaobian will analyze the application of acrylic plate cutting process in detail today. Common acrylic plate cutting usually includes manual hook knife cutting, vibrating knife cutting and laser cutting. Different processes have different advantages and disadvantages.

1. Hook knife cutting

Hook knife cutting refers to manually using the blade to draw a groove on the surface of acrylic plate, and then manually break it. Its advantage is that it has low cost, can be directly operated without early capital investment, and manual operation has strong flexibility. Its disadvantage is that the accuracy of manual operation is low, the edge is not smooth, suitable for linear cutting, and it is difficult to operate for special shapes such as circles.

2. Vibrating knife cutting

Vibrating knife cutting refers to the use of vibrating knife cutting machine for cutting. Its advantage is that different cutter heads can be selected according to the thickness of acrylic. The cutting arc edge is exquisite, and the cutting efficiency is higher than that of laser cutting and manual cutting. Its disadvantage is large tool wear and large initial capital investment. The cutting interval is large and the edge smoothness is low

Laser cutting uses the characteristics of large coefficient of cold and thermal expansion of acrylic plate to achieve the cutting effect by irradiating the surface of acrylic plate with laser beam at high temperature. Its advantage is that the edge is smooth and burr free, suitable for cutting various special-shaped materials, and the operation is simple and convenient. Its disadvantage is that compared with the vibrating knife, the speed of cutting thick acrylic plate is slow, and the edge is not transparent, which needs to be polished in the later stage, and the laser is hot, and the effect of yellow edge can occur when the operation is inappropriate.

Thunderlaser is a manufacturer specializing in the production of laser cutting machines. After many tests and research, acrylic cutting can achieve the effect of no yellow edge, beautiful and perfect. If you need, you can contact customer service to arrange samples!