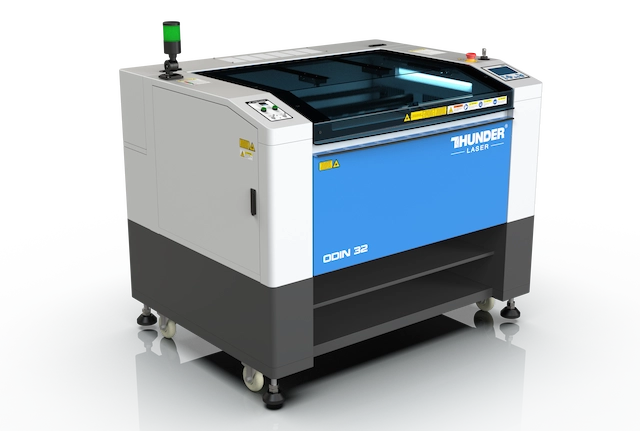

Thunder Laser Odin 32

[Precision & Speed Laser Engraver]

From $14800

Odin 32

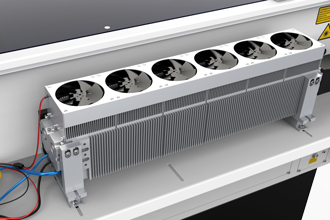

In 2020, Thunderlaser introduced the Odin series laser engraver, a compact and cost-effective solution for high-quality engraving and cutting. With 5G acceleration, an 80 IPS (2000mm/sec) engraving speed, and an air-cooled RF tube, it offers a super-fast laser engraving solution. The minimal gantry payload ensures smooth operation, eliminating the need for a water chiller.

Odin 32

In 2020, Thunderlaser introduced the Odin series laser engraver, a compact and cost-effective solution for high-quality engraving and cutting. With 5G acceleration, an 80 IPS (2000mm/sec) engraving speed, and an air-cooled RF tube, it offers a super-fast laser engraving solution. The minimal gantry payload ensures smooth operation, eliminating the need for a water chiller.

Our Standard Features

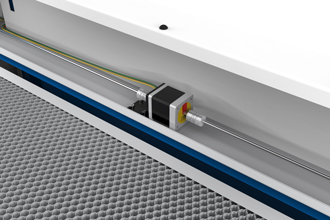

High speed motors

Japanese ORIENTAL motor systems on X and Y axes, with 80 IPS(2000mm/s) and 3G acceleration engraving speed.

New: 100% smoother guide Rail

New: 1,000 DPI RF metal laser source

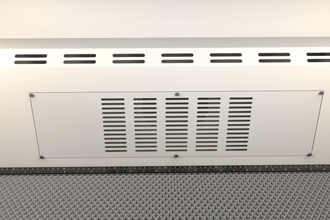

New: Upper & Lower Vent

Dual Air-Assist system

NewEightfold-Open-flap-protection

| Laser System | Odin 22 | Odin 32 | ||

|---|---|---|---|---|

| Laser Tube Wattage | 30 Watt | 55 Watt (Coherent) | ||

| Working Area | 559 x 381 mm (22″ x 15″) | 813 x 508 mm (32″ x 20″) | ||

| Table Size | 625 x 440 mm (24.6″ x 17.3″) | 899 x 567 mm (35.4″ x 22.3″) | ||

| Max Part Size(W x L x H) | 625 x 440 x 190mm(24.6″ x 17.3″ x 7.5″) | 879 x 567 x 190mm(34.6″ x 22.3″ x 7.5″) | ||

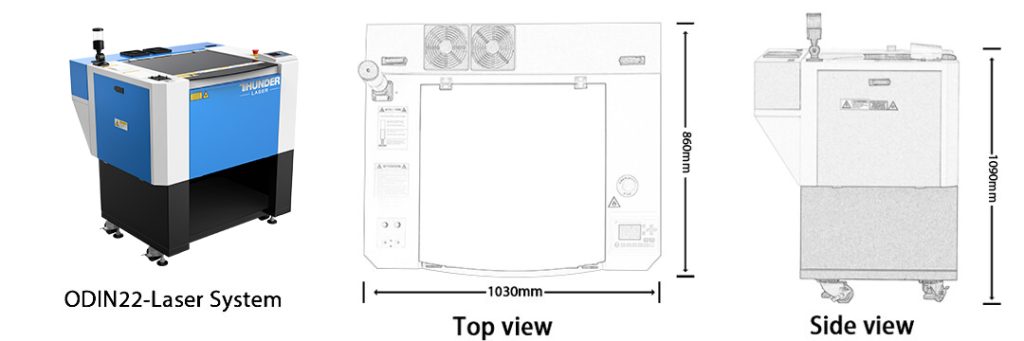

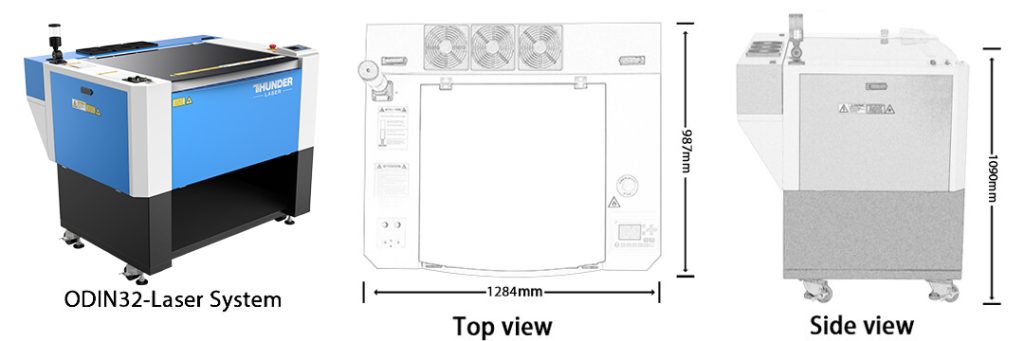

| Dimensions(W x D x H) | 1030 x 860 x 1090mm (40″ x 34″ x 43″) | 1284 x 987 x 1090mm (51″ x 39″ x 43″) | ||

| Laser Type | Radio Frequency Laser Tube | |||

| Cooling | Air Cooled | |||

| Maximum Speed | 2000MM/S | |||

| Maximum machining size at 1000 speed – lightweight laser head | 529 x 381 mm(20.8″ x 15″) | 783 x 508 mm(30.8″ x 20″) | ||

| Maximum machining size at 2000 speed – lightweight laser head | 461 x 381 mm(18″ x 15″) | 715 x 508 mm(28″ x 20″) | ||

| Speed and Power Control | Computer or manually controlled speed and power from 0-100%.Vector color mapping sets speed and power settings using RGB color mapping. | |||

| Operating Modes | Optimized raster,vector,and combined mode | |||

| Resolution(DPI) | User controlled from 100 to 1000DPI(standard laser head) | |||

| Computer Interface | Ethernet and USB Connection | |||

| Compatible Operating Systems | Windows, Mac, and Linux (Mac and Linux with LightBurn Software) | |||

| Buffer Memory | 128MB Standard | |||

| Display Panel | 3.5″ LCD panel showing current file, total working time, laser power, speed, etc… | |||

| Electrical Requirements | Requirements110 to 240 volts,50 or 60 Hz,single phase | |||

| Z-Axis Height | 185mm (7.3″) | 185mm (7.3″) | ||

| Net Weight | 145kgs (320lbs) | 167kgs (368lbs) | ||

| Motion Control System | High-Speed Stepper Motors | |||

| Speed and Power Control(engraving depth) |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. |

|||

| Ventilation System | Integral exhaust fan. There is 1 output port, 5.7″ (145 mm) in diameter in the rear of the case. | |||

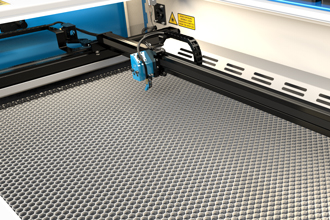

| Workpiece table | Solid metal blades & Honeycomb table | |||

| Max. table load | 20kgs (44lbs) | |||

| Materials | Engrave | Cut |

| Wood | √ | √ |

| Acrylic | √ | √ |

| Delrin | √ | √ |

| Cloth | √ | √ |

| Leather | √ | √ |

| Mat Board | √ | √ |

| Melamine | √ | √ |

| Paper | √ | √ |

| Mylar | √ | √ |

| Pressboard | √ | √ |

| Rubber | √ | √ |

| Wood Veneer | √ | √ |

| Fiberglass | √ | √ |

| Plastic | √ | √ |

| Cork | √ | √ |

| Corian | √ | √ |

| Twill | √ | √ |

| Anodized Aluminum | √ | X |

| Painted Metals | √ | X |

| Tile | √ | X |

| Glass | √ | X |

| Coated Metals | √ | X |

| Ceramics | √ | X |

| Marble | √ | X |

| Stainless Steel | * | X |

| Brass | * | X |

| Titanium | * | X |

| Bare Metal | * | X |

Optional Items

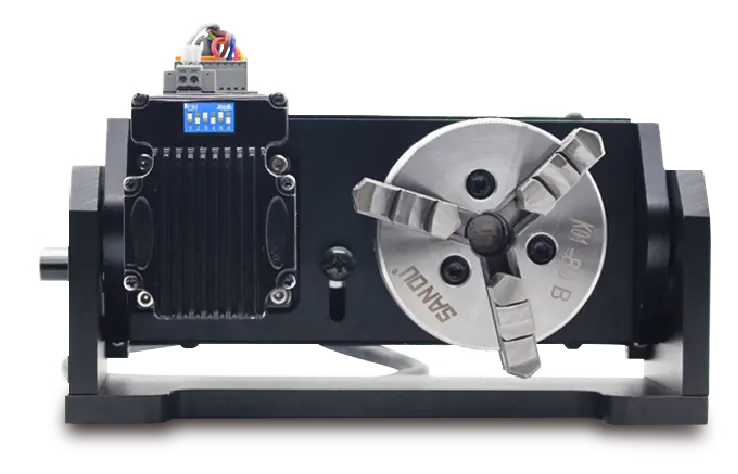

Rotary for Bolt and Plus

Provides precise processing on cylindrical objects for Bolt and Plus, enhancing your laser processing capabilities.

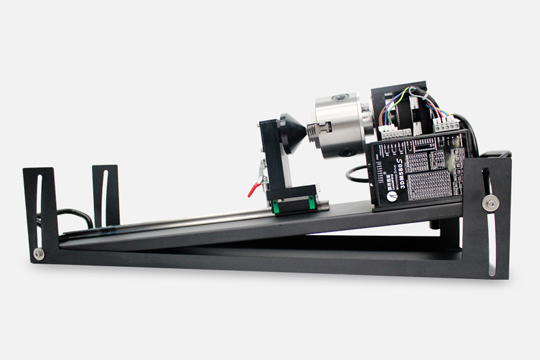

Rotary for Bolt Pro

It enables precise processing on cylindrical objects for Bolt Pro, ensuring accurate processing of bottles, glasses, and more..

Focus Lenses

Lenses available for all project types. The more detailed the graphics, the shorter the focal length. The thicker the material, the greater the focal length is required.

Lightburn DSP License Key

Install a removable rotary in your laser engraving machine for cylindrical glass, wood, or metal products.

Thunder Laser Odin Series

The Odin series laser engraver and cutting machine combines a compact size, with high-quality engraving and cutting at a low cost. This Laser machine is intended for very high-detail engraved and minimal cutting.

- 2,000mm/sec Engraving speed

- Speed & Accuracy RF Laser Tube

- Australia based customer service

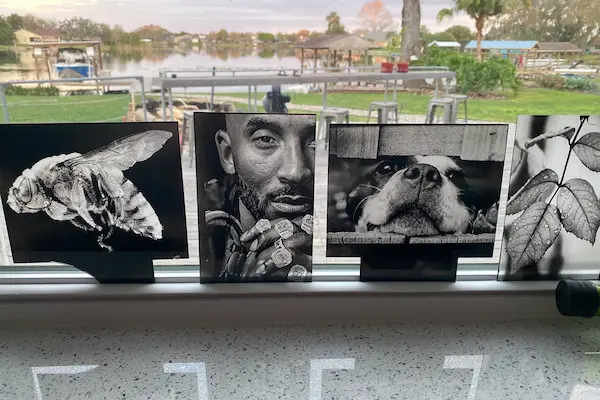

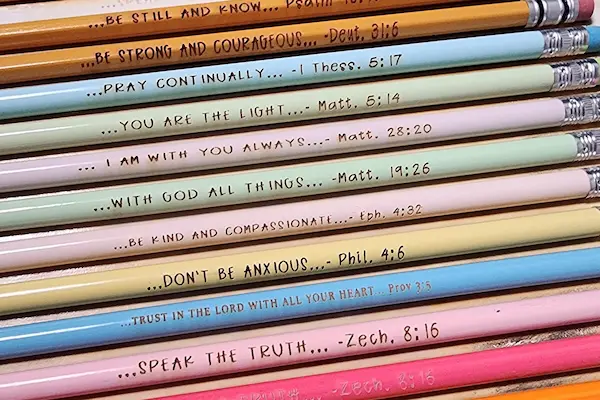

Application

Our engraving and cutting machines empower you to push the boundaries of endless possibilities.

What Our Customers Say About?

Lisa Turnbull

Transformative! After a failed attempt with a ‘hobby’ laser a year ago, our Thunderlaser engraver turns the tide. Tonight, success with precision crafting, redefining our journey

Rob Nance

Consulted with Glenn at Thunder Laser about my project goals, and he provided valuable assistance. Settled on the Odin32 laser engraver and couldn’t be happier. Thanks to Glenn and the entire Thunder Laser team!

Jason Dow

Outstanding components, meticulous assembly, exceptional people. Thunder Laser offers unparalleled value for a laser engraver! Highly recommended.

Belinda Fancett

Mandy was extremely helpful in answering all of my questions promptly as I was researching what Laser to purchase as my very first laser engraver.

Kelsie Donant

Undecided about my laser purchase, Glenn’s guidance was invaluable. With exceptional patience, he addressed my questions, providing unwavering support for choosing a laser engraver.

Tommy Norris

Undecided about my laser purchase, Glenn’s guidance was invaluable. With exceptional patience, he addressed my questions, providing unwavering support for choosing the right laser engraver.

Frequently Asked Questions

No need. We’ve added a parameter library in the software, once you find out what settings is best for a certain material;you can record it in the parameter library. Next time you cut the same material, you just need to read it from the list.

You can use your Thunder Laser machine from your Mac, PC, and more to connect with it. You’ll just need a USB-PC Cable or Ethernet Cable.

Utilizing software like LightBurn, RDworks, and Adobe Illustrator, you have the capacity to create designs. Thunder Bolt has the capability to print various file formats including JPG, PNG, SVG, PDF, and more. The process of printing a file is as simple as transmitting it to our Laser Machine, followed by fine-tuning the preview according to your preferences.