Small laser engraving has become a new processing method because of its precise, convenient, fast, simple operation and high degree of automation. It has been widely used in the leather industry, especially. Here we introduce the application of small craft laser engraving machine in leather processing.

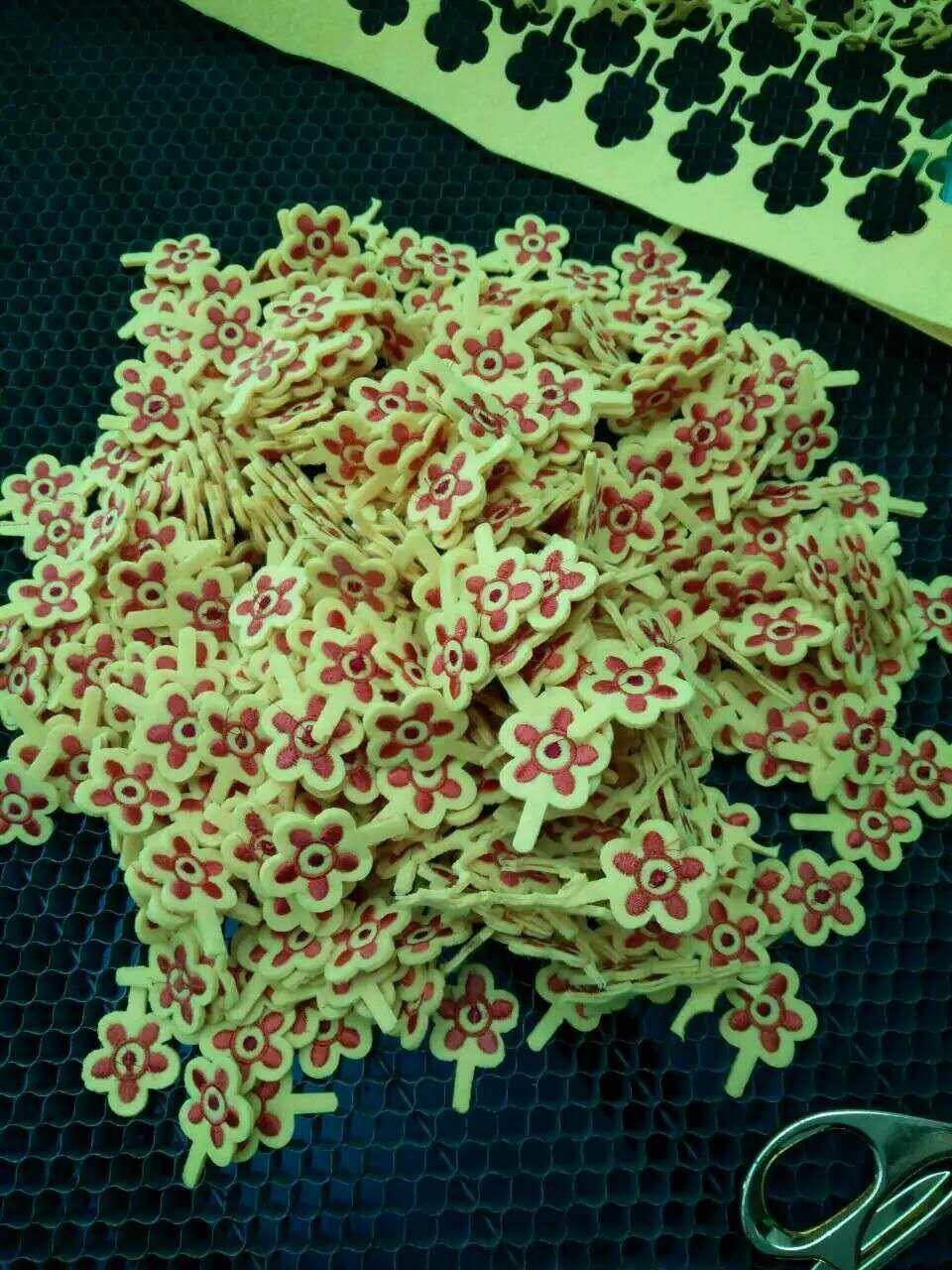

Small craft laser engraving machine technology is widely used in shoemaking and leather industry. The advantage of small craft laser engraving machine is that it can quickly carve and hollow out all kinds of patterns on all kinds of leather fabrics, and the operation is flexible. At the same time, it will not cause any deformation on the leather surface, so as to reflect the color and texture of leather itself. It has many advantages, such as high carving precision, no burr, arbitrary shape selection and so on. It is suitable for the processing and production of vamp, shoe material, leather goods, handbags, bags, leather clothing and so on.

More than two-thirds of textile and garment fabrics can use small craft laser engraving machine to make various digital patterns. The traditional textile fabric production process needs the later grinding, hot stamping, embossing and other processing processing, while the small handicraft laser engraving machine has the advantages of convenient production, fast, flexible pattern transformation, clear image, strong three-dimensional sense, and can fully show the true color and texture of various fabrics, as well as the long-standing advantages. If it is combined with the hollowing out process, it will make the finishing point and complement each other. It is suitable for: textile fabric finishing factory, fabric deep processing factory, garment factory, surface accessories and processing enterprises.