1) You pay the 30% deposit to us

2) We prepare the machine for you after we receive your money.

3) We take photos/video for you when the machine is ready.

4) You pay the 70% balance to us after you see the photos and videos.

5) We send out the machine to you by sea way to your sea port(or by DHL to your door directly according to your needs)

6) We send out all the documents to you to clean the customs and get the machine.

7) The shipping company will contact you when the machine arrives at your port. You contact with shipping company and ask them to help you to clean customs. And then ask them to find a carrier to send the machine to your door.

8) Everything is done now.

Let’s say sending a machine to Hamburg port. Usually, the total delivery time to Hamburg is about 42 days by sea way.

1) The time to prepare the machine is about 7-10 days,

2) We send the machine to the shipping company and the machine will stay in the shipping company’s warehouse for about one week. This is called LCL period.

3) the time from China port to Hamburg port is about 25 days.

Usually, we will need about 7-10 days to prepare the order after receiving the payment.

And if send by DHL air way, it will need about 7 days to reach you.

So totally it will need about 14-17 days if you choose DHL air way to your door.

Thunder Laser Parts Only Warranty

Warranty is dated from the day the system is shipped within Australia. Thunder Laser will work

with you to diagnose the part failure through discussion, photos and videos. Under warranty,the

replacement parts will be sent without charge. Our free tech support is available for the life of

the machine through most virtual platforms.

Thunder Laser parts only warranty is valid for Thunder Laser customers who have bought their

machine from January 2022.

Yes. If you are looking for tech support of your Thunderlaser system, here are the guidance to help you to get answer faster:

– Search for solution from Thunderlaser website-Troubleshooting.

https://support.thunderlaser.com.au/portal/en/kb/thunderlaser-australia

– Email Thunder Laser Australia

Email: sales@thunderlaser.com.au

– Phone Thunder Laser Australia directly

Glenn 0407 963 306

– Skype: thunderlaser

– Email: tech@thunderlaser.com

we will always be here for Thunderlaser users.

you can read the detail from our website:

Yes. Our Nova laser systems come preset and tested through our quality assurance program. Thunder Laser machines come with a water chiller, air compressor, exhaust fan, tool box with all accessories needed to set up and run.

As long as you know how to design jobs in graphic software, it just takes a few hours for you to become a master of laser machine.

You just need to do some tests to know what speed and power is good for different materials. Since we’ve provided some of the

parameter library, it will save you more time.

You can watch the guiding videos from our website to learn how to use the machine in advance too.

https://www.thunderlaser.com.au/what-laser-cutter-can-create

https://www.thunderlaser.com.au/how-to-use-your-laser-machine

https://www.thunderlaser.com.au/how-to-use-your-laser-software

Please watch this video directly to learn the detail

No, our laser machine can do both cutting and engraving very well.

You just need one machine for both kinds of jobs.

yes, every machine will wear. However, you don’t have to worry about that. The machine will be working normally at least 2-5 years.

After that, you may need to change the parts. And all the parts can be replaced. We will charge at a fair price.

Higher watt tube with more power can cut thicker materials, or we can say, for cutting same material, higher watt tube can achieve faster speed.

However, theoretically speaking, the lower watt tube with smaller laser power, which is better for engraving. Usually we suggest 40-80 for engraving, 100-130w for cutting.

Yes, we have maximum 130watt laser power for your choice.

the standard model is 10CM diameter

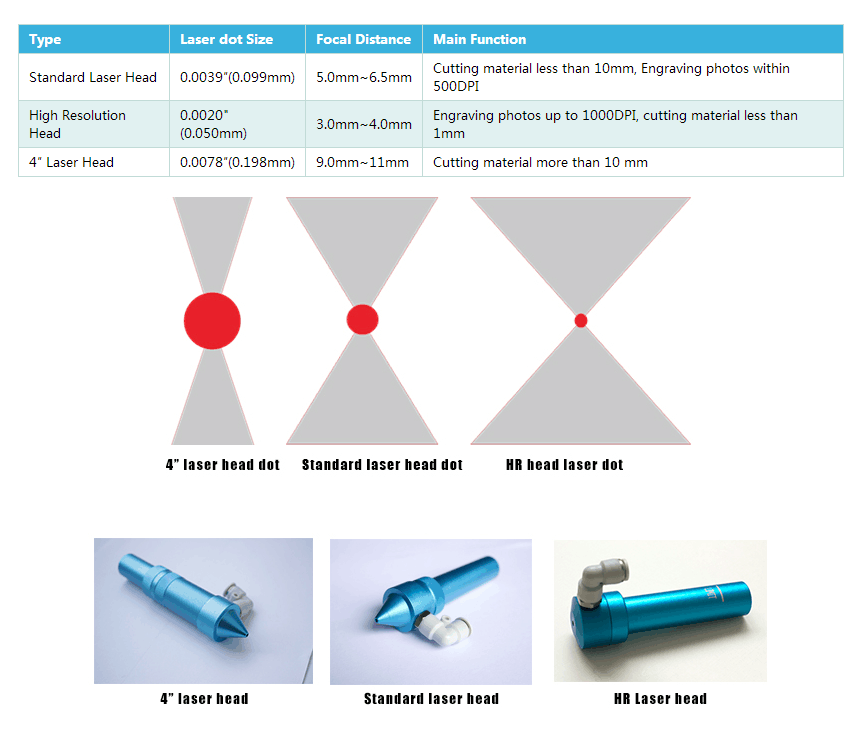

The standard focus lens is 2”; there is 4″ for your choice.

Shorter focus lens will have smaller final beam diameter. That’s why it is better for engraving good quality photos.

And longer focus lens is better for cutting thicker materials.

For a laser with less than 80W and clean engraving jobs I would recommend the Silicon-Mirrors because they have the best

reflectivity (>99%).

For a laser who is doing very dirty work (cutting wood 8 hours a day) or working with aggressive chemicals I would recommend the

Molybdenum-Mirror. The reflection coating (there is no coating, the Molybdenum is just polished) is very resistant and can get cleaned

very easily. Even if the reflectivity is only at 98.5%, the Mo-Mirror is almost unbreakable.

Yes. We have

Open flap protection switch, the laser will stop working if you open the front cover. Water protection, Laser will stop working if the water cooling system is not working normal. Emergency stop, Turn off the machine immediately when there’s accident happen. Alarm Lamp, show the work state and tell when the job is done. Heat Alarm detector, the laser machine will warming with loudly voice if cutting material catch fire.

There’s an exhaust fan comes with the machine.

Yes, Red dot laser pointer is standard feature of all Nova machines.

The normal color of the laser beam is purple while working. When a tube is dying, the color will become white.

Usually, the power of the tube is decided by two parameters:

1. The length of the tube, the longer the tube is the more powerful.

2. The diameter of the tube, the bigger the tube is the more powerful.

No, we don’t suggested that.

A more powerful supply may damage the laser tube.

No need.

There are two ways to adjust the focus.

1) You can adjust the laser head manually

2) Use a motorized up/down table (auto focus)

Yes, the co2 tube is controlled by the power supply. And the power supply is controlled by the controller. And you can set the power

rating easily in the software.

High resolution Attachment will make the laser dot smaller, thus you can have much better engraving quality.it is used to engrave

extremely high quality photos.

For the engraving distance,

With standard 2″ laser head, the distance between laser head and material is 5mm-6.5mm.

If cutting thick material and 6mm distance does not give a good result, you can try adjusting the distance down to about 5mm. For

details, please contact with our tech person.

For cutting some thick materials, it is correct.

But when engraving on some materials, it’s better to use less powerful air pressure.

The normal life tube of a laser tube is about 2500-4000 hours according to how you use it.

Yes, footstand of desktop laser machine is an option. We will take it apart for shipping and you can set it up with screw later on.

Usually it’s suggested to leave about 200mm space for the backside to install the exhaust pipe.

For the other sides, need about 100mm for each, but when you need to replace the parts of the machine, please move it out to a wide place.

The USB connection is on the right side of the machine, please have a look at the pic.

Yes, we have pass-through door design for our machine:

https://www.thunderlaser.com.au/how-to-use-your-machine/pass-through-door-design.html

You have to replace a new tube when it’s no longer working.

It’s not cost-efficient to recharging a co2 glass tube.

Usually we will pack it well and it’s seldom out of alignment,

Once it happens, we have video and lesson to guiding you how to align the laser beam:

If the beam is a small round dot, then it is perfect,

but in fact, most of the beam are close to round dot.

If you just realign the parts without reading our technical lesson or guiding video,

It’s unsafe indeed even you wear laser safety glasses,

However, if you realign them by following our lesson and video step by step,

It’s not so dangerous,

And to make it safer, you can wear a pair of laser safety glasses,

Please note the most important thing is: familiar with the process of lesson and video.

No unsafe materials, and yes, they can be disposed of safety.

According to our customers’ feedback, life for the belts should be at least 3-5year.

When you find it is loose, you can adjust it by reading our user manual and watch guiding video:

Yes, machine will get dirty after using for a period time,

Then you should clean and maintain it frequently.

For how to clean the machine and make maintenance,

Please read our user manual from page 47-56.

For cutting thick material (usually more than 10mm),

4″ lens is good for getting a more straight/smooth edge, but it does not mean you can cut more depth.

For exhausting the air outside,

standard length for the hoses is about 6m

is it ok for you?

if not, can you please tell me how long do you need?

I think we can offer special hoses to you,

for outputting the air,

it’s depend on your material,

if you use the laser for cutting wood/acrylic/leather/fabric, etc.,

it’s ok, no dangerous, but some or less smell I think.

and material like PVC/Vinyl contains chlorine are not suggested to cut with laser.

(its fume dangerous for human health and will corrode the machine.)

Please find below link for how to move the laser cutter into your house, thanks.

No need. We’ve added a parameter library in the software, once you find out what settings is best for a certain material;

you can record it in the parameter library. Next time you cut the same material, you just need to read it from the list.

Both laptop and desktop are suitable. Our lasers are compatible with Windows 7/8/10/11 including 32bits and 64bits system, as well as Mac O/S through lightburn.

CorelDraw and AutoCAD are suggested. You can design all your artworks in these two software and then send to the RDWorksV8

software to set the parameters easily.

JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA,

PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW

Yes.

Yes, you can take a photo by using a camera and then load the photo to the software directly and engrave it.

Yes, we welcome you to send us a file and we will make a sample for you to have a look.

Yes, you can start the software without laser machine.

The corner power should be less than the max power, since the laser head moves slower at corners. For how much less, it is best to do

some tests until you find the best one.

Yes, it’s ok to use files from Adobe Illustrator, but you will need to export it as DXF format. Then our software can load it directly.

Yes, it does support AI plug-in. However, at present, almost all Chinese Laser software cannot support AI plug-in very well. Sometimes

there’re some unknown problems if you use AI plug-in directly.

We would suggest you to export your AI files as DXF format, then our software can support it perfectly.

For CorelDraw X2, X3, X4, X5, X6, X7 our machine can support it directly.

DXF format, but there’s plug-in for coreldraw, so you can switch from coreldraw to our laser software directly.

Yes and no.

Our laser machines can engrave on anodized metal and painted metal directly.

But it cannot engrave on bare metal directly. (This laser can only engrave on a few parts of bare metals directly by using the HR

attachment at a very low speed)

If you need to engrave on bare metal, we would suggest you to use thermark spray.

www.thermark.com

Max cutting thickness for acrylic:

40watt:10mm

60watt:13mm

80watt:18mm

100watt: 20mm

130watt: 25mm

Yes, our laser engrave 3D, like relief.

See below video:

https://www.thunderlaser.com.ua/what-laser-cutter-can-create/3d-laser-engraving.html

No, for cutting metal, you will need at least 200watt laser.

We only focus on cutting non-metals at present.

However, by using a thermark spray. Our laser can also engrave on metals.

Yes, please download from below link directly

Yes, we can cut POM. Please tell us the thickness, we will recommend you a well machine.

For the workable materials, please learn the details from our website:

Please do not cut any material containing chlorine like PVC, Vinyl, etc. and other toxic material.

when heated releases chlorine gas.

This gas is toxic and poses a health risk as well as being very corrosive and harmful to your laser.

Yes, normally cast acrylic is better than extruding acrylic for laser processing.

We didn’t test for engraving photos on metal with Thermark before,

and according to our experience, we think it should be not so good,

as you know metal become black after engrave with laser,

for engraving word, logo and simple pattern, it’s good to see it clear,

however, for engraving photos, I am afraid it’s hard to get a gray scale photo .

Yes, Anodized Aluminum is the best material for engraving photos.

and Color Anodized Aluminum is the best among the Anodized Aluminum sheets.

then Acrylic, ABS is also very good if you have a good quality ABS,

(ABS is a kind of plastic, some ABS will be bend after heat by laser).

No, our laser(co2 laser) can only engrave on surface of material/glass/crystal,

Yes, you can do more than one cut, but usually it’s not suggested to cut twice. Most of the time, one cut will get the best cutting quality.

The material we paste on glass is just a kind of common tissue paper,

since it help us to get a more smooth surface, (no so much rag)

it’s ok, you really needn’t worry about the paper, you just need to make it wet,

and then paste on the surface of glass you want to engrave.

for Thermark, yeah, it’s useful for engraving on metal,

and after you get the laser job down, you can tear the Thermark off,

(there’re 3 types of Thermark, you can visit their website if you like to learn more)

then you can get a clear pattern/words on metal.

10-15mm

All rights reserved ©2023 Thunder Laser Australia | Sitemap